In the rapidly evolving field of machine vision, precision and reliability are paramount

Chroma Technology is at the forefront of this revolution, providing cutting-edge optical filters that are essential for today's automated systems in manufacturing, robotics, and quality control.

Our filters play a crucial role in enhancing image clarity, color accuracy, and contrast in the machine vision applications where every detail matters.

Our team, leveraging decades of experience in optical engineering, collaborates closely with our machine vision customers to provide free application and design support.

We ask the right questions and apply our extensive knowledge to deliver filters and optical solutions that are enabling the next generation of machine vision and automation.

Advanced optical solutions for complex machine vision challenges

Our team, leveraging decades of experience in optical engineering, collaborates closely with our machine vision customers to provide free application and design support.

We ask the right questions and apply our extensive knowledge to deliver filters and optical solutions that are enabling the next generation of machine vision and automation.

For over 30 years, Chroma has been at the forefront of optical filter innovation, providing solutions that are critical in the fast-evolving automation industry. We've been the trusted partner for organizations demanding high precision and reliability in challenging environments for decades.

Custom Band-Width and Band Placement

Chroma can address unique machine vision challenges with our custom solutions.

Figure 1: 470nm LED spectrum, traditional ~60nm wide bandpass filter, and 20nm wide bandpass filter

Figure 1: 470nm LED spectrum, traditional ~60nm wide bandpass filter, and 20nm wide bandpass filter

Traditionally, machine vision systems have relied on bandpass filters with bandwidths of 60nm or more, and generally centered over common LED wavelengths. Narrower bandwidths, for example, 20-40nm wide, cut out the “tails” of the LED output spectrum where there might also be background light, or noise.

Figure 2: Examples of 1064nm laser clean-up bandpass filters with FWHM of 0.5nm, 2nm, and 7nm.

Figure 2: Examples of 1064nm laser clean-up bandpass filters with FWHM of 0.5nm, 2nm, and 7nm.

For laser applications, an even narrower band (< 20nm) can be used at the laser source to “clean-up” the laser which might have noisy amplified spontaneous emission (ASE). In Figure 2 above are examples of narrow bandpass filters for cleaning up a 1064nm laser.

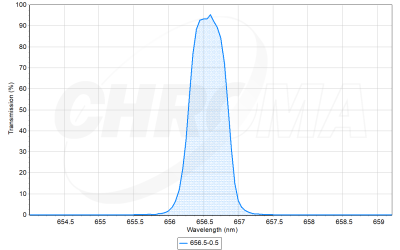

Figure 3: Ultra-narrow bandpass filter for hydrogen detection.

However, there are scenarios where even narrower bands are essential for optimal results, for example when dealing with the chemical composition of materials. In these cases, custom filters with extremely narrow bandwidths, < 10nm down to 0.5nm FWHM (full-width half-max), can isolate a spectral signature so an instrument can find a needle in a haystack. These narrow bandpass filters offer remarkable advantages in material analysis applications by precisely isolating a small sliver of spectral information, enhancing contrast, and improving accuracy.

Integrating narrow bandpass filters into machine vision systems for material analysis requires careful consideration of several factors, including the specific application requirements, lighting conditions, and the spectral characteristics of the materials. Customization and optimization play a vital role in achieving the desired performance and maximizing the benefits of these filters in material analysis tasks.

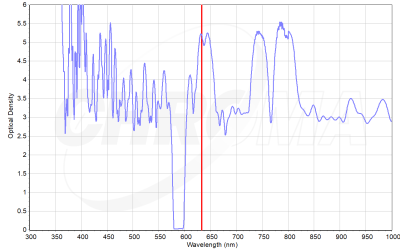

Figure 4: 590-20 machine vision filter with OD5 blocking of a 632.8nm He-Ne laser

Laser light in the field

In the context of machine vision, it is not uncommon to encounter scenarios where laser light is present in the imaging field. For instance, when a laser profiler is utilized, it becomes crucial to block the laser light to prevent it from overwhelming the captured image. In such cases, it may be necessary to employ filters with a higher optical density to increase attenuation.

Interference filters with high optical density at the laser line over a wide range of angles can effectively block the laser light from contaminating the image while maintaining excellent image quality. Interference filters are easily customizable which enables you to selectively increase the blocking for specific laser wavelengths as needed, without compromising cost-effectiveness.

Using higher optical density filters with high angle tolerance efficiently blocks laser light, minimizing interference and maximizing visibility and clarity of desired objects or features in the machine vision system. This enhances analysis accuracy and reliability, optimizing system performance. When dealing with laser light in machine vision applications, it's crucial to consider custom filter solutions. Leveraging interference filters effectively controls laser light's impact on the imaging field, ensuring accurate and reliable image analysis while managing costs efficiently.

Multibands filters for when you have multiple light sources coming on sequentially

In systems with multiple LEDs, the implementation of multiband filters combined with strobing techniques can lead to cost savings by reducing the reliance on expensive cameras. This multispectral approach enables the use of a single camera without the need for a filter-wheel.

Sorting recycled materials utilizing these filters alongside multiple LED light sources that are sequentially turned on and off, various applications can benefit. For instance, this concept can be employed to assist in identifying glass, aluminum and plastic for sorting and inspection of recycled materials.

Figure 5a: A quad-band machine vision filter spectral transmission

The utilization of multiple bands provided by the multiband filter empowers the inspection system to gather additional information rapidly as the line moves swiftly. This wealth of information is instrumental in distinguishing between desirable and undesirable materials, detecting the presence or absence of certain substances, and even identifying the specific type of material or substance present.

Figure 5b: Example of how multiple LEDs strobing sequentially while a camera with a multiband filter captures images can sort recycled materials

Figure 5b: Example of how multiple LEDs strobing sequentially while a camera with a multiband filter captures images can sort recycled materials

Benefits of using Chroma filters in machine vision applications

Better image quality and more accurate color reproduction

In machine vision, where every detail matters, achieving superior image clarity and accurate color reproduction is essential. Our machine vision filters are designed to elevate your system's performance by enhancing image quality and ensuring precise color fidelity and contrast.

Experience clearer images, even in challenging lighting or environmental conditions for accurate analysis. This accuracy is vital for reliable automated processes, helping your system to see and interpret the world with greater precision.

By focusing on these key aspects, our optical filters not only improve the visual output of your machine vision systems but also contribute to their overall efficiency and reliability. Chroma machine vision filters are engineered to deliver unparalleled image clarity for applications where precision and detail are of the utmost importance.

Easy integration

Seamless integration is key in machine vision technology.

At Chroma, we understand that compatibility and ease of use are as important as the technical excellence of our optical filters. To support ease of use, our filters are designed to seamlessly integrate with a wide range of machine vision systems, from standard industry cameras to cutting-edge and custom-built hardware.

With our wide range of standard sizes and the ability to customize to unique specifications, integration becomes a simplified process, enhancing system efficiency and reducing setup times.

Durability in harsh environments

We understand that durability means more than just surviving tough environments; it means maintaining peak performance over time.

Chroma filters are made to adhere to stringent industry environmental and durability standards, including ISO and MIL specifications for abrasion resistance, adhesion strength, and resilience against extreme temperatures, humidity, salt fog, and laser damage thresholds.

This long-lasting durability translates into cost savings and reliability for our customers, ensuring that our filters remain a dependable component in any machine vision system, regardless of the operational challenges it faces.

Customized solutions

Understanding that every machine vision application is unique, we offer customized solutions in addition to our catalog machine vision filter offerings. At Chroma, we build optical filters for use from the UV to the IR and made to fit systems from all of the major camera manufacturers.

But don’t worry! If you have a lesser used camera model, a custom built system, or even if you’re lucky enough to have the latest and greatest in machine vision tech, we can customize filters to most any size or shape required to integrate in your system.

Explore the full range of our manufacturing capabilities, then contact our engineering team to help you design the perfect optical filter for your machine vision system.

Machine vision applications of Chroma's optical filters

Our filters play a vital role across various machine vision applications, ensuring performance and reliability where it matters most. Chroma's filters are integral to:

Agricultural automation

Environmental monitoring

Food sorting

Industrial automation

Quality control and inspection systems

Robotic guidance

And many other advanced automation, inspection, and industrial applications

And these applications are just the tip of the iceberg. Our filters are integral to a wide range of advanced machine vision applications, each with its unique challenges and requirements that Chroma is ready to meet or exceed.

Partnering for your success: our engineering support

Understanding that every machine vision application is unique, our experienced engineers work alongside you to offer customized solutions for even the most challenging applications.

Whether it's optimizing costs, enhancing system performance, or sharing expert knowledge, we're here to ensure your machine vision system excels in every aspect.

Our focus is not just to provide answers, but to discover the right solutions for your specific needs. From the initial consultation to ongoing support, we're dedicated to assisting you at every step, ensuring your Chroma filters deliver optimal system performance for years to come.