Optical Filters for Semiconductor Inspection and Metrology Applications

In the world of semiconductor manufacturing, where nanoscale precision can make or break a product, optical filters play a crucial yet often overlooked role. At Chroma Technology, we understand that the quality of your optical filters directly impacts the accuracy of your inspection processes and ultimately, the performance of your semiconductors.

Chroma: Your Partner in Semiconductor Inspection

We specialize in creating advanced optical filters designed to meet the rigorous demands of semiconductor inspection including filters for:

Defect detection

Detecting and categorizing defects on wafer surfaces is essential for maintaining the quality and performance of semiconductors. Our filters enable high-precision detection, ensuring minimal defects in the final product.

Laser-based inspection

Laser-based inspection techniques, including measuring thermal conductivity and resistance, rely on high-quality optical filters. Chroma’s filters ensure precise and reliable measurements which are essential for optimizing semiconductor performance.

Material characterization

Understanding the properties of materials used in semiconductor manufacturing is vital. Our filters aid in detailed material characterization, providing valuable insights into material quality and performance.

Overlay accuracy inspection

Achieving precise overlay accuracy is critical in semiconductor manufacturing to ensure that successive layers are perfectly aligned. Chroma filters help you achieve superior accuracy in detecting and correcting overlay deviations.

Particle detection

Accurate particle detection is crucial to avoid contamination and ensure the longevity and reliability of your product. Chroma's filters are designed to enhance the sensitivity and accuracy of particle detection systems.

Sub-surface inspection

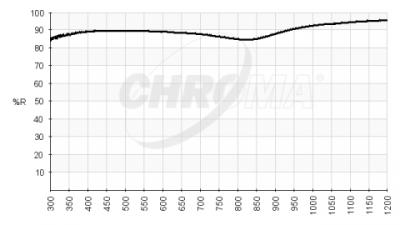

Utilize the short-wave infrared (SWIR) range to see through layers and uncover hidden defects. Our filters offer the spectral performance needed to detect issues unseen in the visible spectrum.

While these applications represent some of our core strengths in semiconductor inspection, our expertise extends far beyond these areas. Whatever your semiconductor inspection needs may be, we're committed to developing specialized optical filter solutions that push the boundaries of precision and performance. Chroma filters offer a range of benefits including:

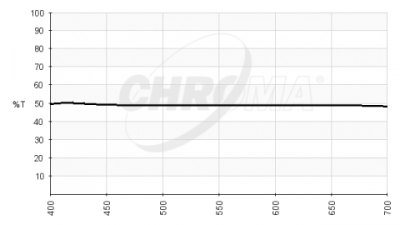

Precise Wavelength Selection

In semiconductor inspection, the ability to isolate and analyze specific wavelengths of light is crucial for detecting the finest details and subtlest defects. Chroma filters offer unparalleled control over light, with features designed to enhance your inspection capabilities:

High transmission for maximum signal strength

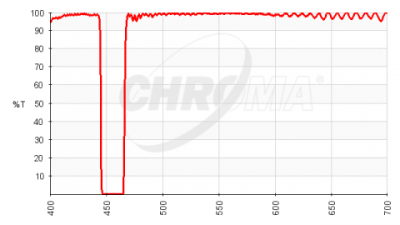

Deep blocking to reduce noise, with full range out-of-band blocking available

Steep edges for enhanced spectral discrimination

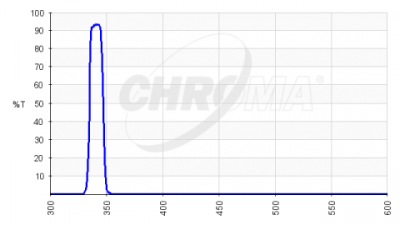

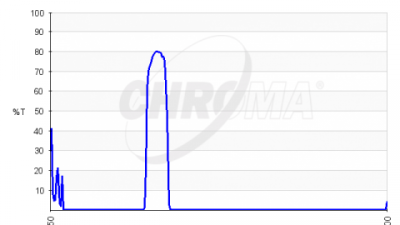

Customizable bandwidths from an ultra-narrow, one angstrom wide bandwidth to a band spanning hundreds of nanometers

These features enable everything from highly selective laser-based measurements to broad-spectrum analysis of semiconductor properties, providing you with the versatility needed for comprehensive inspection processes.

Superior Optical Performance

Beyond wavelength selection, the overall optical performance of filters plays a critical role in the accuracy and reliability of semiconductor inspection. Our filters are engineered to meet and exceed the exacting standards of the industry:

Excellent image quality with low reflected and transmitted wavefront distortion

Low phase retardance for polarization-sensitive applications

High durability for demanding industrial environments

With these advanced features, Chroma filters provide a robust foundation for your semiconductor inspection needs, enabling you to push the boundaries of what's possible in quality control, process optimization, and materials characterization.

Commitment to Quality and Consistency

We understand that the reliability and consistency of our filters are critical to your processes. That's why we maintain rigorous quality control measures throughout our manufacturing processes. As an ISO-certified company, we adhere to strict standards in our operations.

In addition, our comprehensive quality assurance procedures ensure that every filter we produce consistently meets your exact requirements, providing you with the confidence and peace of mind needed for your critical inspection applications.

Filter Options for Different Use Cases

Our extensive experience in creating filters for semiconductor applications includes:

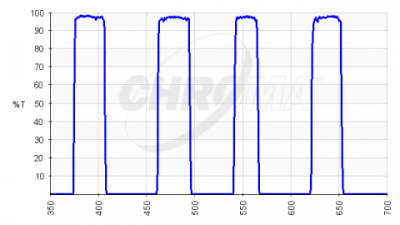

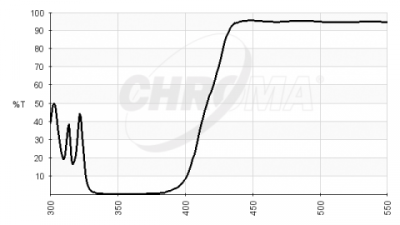

Single & Multiband Bandpass Filters: Select specific wavelength ranges for targeted inspection.

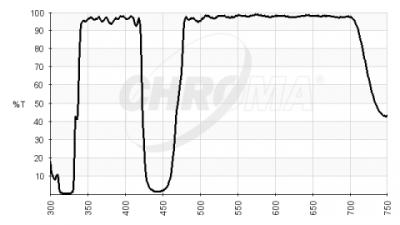

Beam Combiners & Beamsplitters: Divide light beams for simultaneous multi-path analysis.

Dichroic & Polychroic Mirrors: Reflect specific wavelengths while transmitting others. Separate light into distinct wavelength bands.

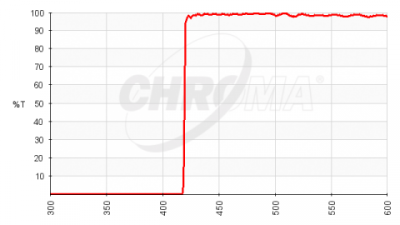

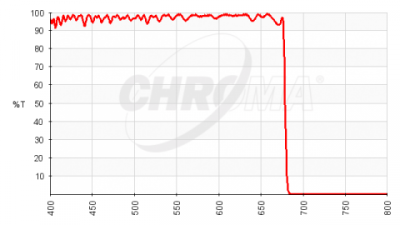

Longpass & Shortpass Filters: Pass either longer or shorter wavelengths while blocking the opposite, enabling precise spectral separation.

Notch Rejection Filters: Block specific wavelengths, allowing others to pass through.

These filter types represent just a fraction of our capabilities in the semiconductor sector. Our extensive experience allows us to address a wide array of optical filtering needs in semiconductor inspection and manufacturing processes.

Filters for Your Light Source

At Chroma, we maintain an extensive inventory of filters, many of which have been specifically designed for a wide range of light sources used in semiconductor inspection, including:

Lasers

LEDs

White Light Sources

Combination Sources

Our comprehensive selection of inventory spans the entire spectral range from ultraviolet (UV) to the short-wave infrared (SWIR), ensuring compatibility with a diverse range of light sources. With our vast array of existing designs, we can often quickly customize the size of the filters to your requirements and ship fast to minimize lead times.

Catalog Filters for Semiconductor Inspection

For the most common filters required, we also offer a range of catalog options which are frequently used in semiconductor inspection applications including our:

Step-by-Step Custom Filter Design Process

For filter designs outside of our catalog offerings, we pride ourselves on our ability to meet even the most challenging filter requirements. Our design process ensures that you get the optimal filter for your application every time with our step-by-step process:

Consultation: First, our team will collaborate with you to thoroughly understand your specific needs and application challenges.

Design Optimization: With our extensive database of over 20,000 unique filter designs, we tailor solutions to meet or exceed your application requirements while optimizing for cost-effectiveness. Whether adapting an existing design or creating a new one, we ensure you achieve the best performance without paying for unnecessary features.

Simulation and Prototyping: We use proprietary optical modeling tools to simulate filter performance and, when necessary, create prototypes for testing.

Manufacturing: Once the design is finalized, we produce your filters using our state-of-the-art facilities, ensuring the highest quality and consistency.

Quality Assurance: Every filter undergoes rigorous testing to meet our exacting standards and your specific requirements.

With decades of experience manufacturing optical filters for demanding applications, we understand the unique challenges you face. Whether you need a minor modification to an existing design or a completely novel filter, Chroma's expertise ensures you receive the best performance and value possible, tailored precisely to your application.

Ready to Enhance Your Semiconductor Inspection & Metrology?

Contact our team to discuss your specific requirements or request a quote.