Optical Filters for Short-Wave Infrared (SWIR) Applications

Short-Wave Infrared (SWIR) technology is critical for advanced imaging and sensing applications, offering unique capabilities to detect details invisible to the human eye and traditional cameras. In addition, SWIR wavelengths (1-3um) are used for telecommunications and in particular laser-based free-space optical communications such as for satellite communication (or SatCom) applications.

At Chroma Technology, our sputter-coated optical filters are designed to meet the demanding needs of SWIR-based systems, providing high transmission, precise wavelength control, and durability.

Filters for Key SWIR Use Cases

Our SWIR filters are engineered to deliver precise spectral performance in several key applications, including:

Food Inspection

SWIR filters help detect bruises, moisture, and other defects in food products, enabling quality control and food safety in automated processes such as packaging and inspection.

Hyperspectral Imaging

Separate specific wavelengths for detailed analysis across spectral bands, aiding in material differentiation and multispectral imaging.

LIDAR Systems

Offering filters with low sensitivity to angle of incidence, our SWIR filters are ideal for distance measurement and mapping in autonomous vehicles, aerial surveys, and environmental monitoring.

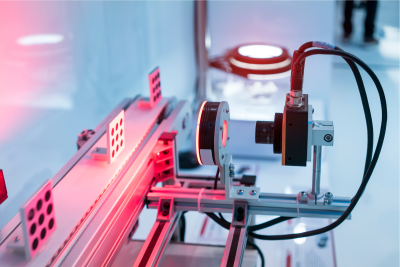

Machine Vision

Inspect material properties invisible to the eye, improving accuracy in sorting and defect detection for high-speed industrial machine vision systems.

Materials Analysis

Detects chemical compositions, moisture, internal defects and detection of leaks and contaminants for environmental and industrial safety.

Remote Sensing and Agriculture

Capture data on vegetation health, soil moisture, and water content, enabling smart farming and environmental monitoring with drones and satellites.

Semiconductor Inspection

Improve manufacturing processes by seeing through the layers to detect defects and verify overlay accuracy.

These applications demonstrate the versatility of our SWIR filters across a range of industries. Whatever your SWIR system requirements, Chroma is committed to providing high-performance, durable filter solutions.

Optical Filters for High Transmission in the SWIR Range

High transmission is critical for SWIR systems thus ensuring that the maximum amount of light is captured and transmitted. Chroma’s sputter-coated SWIR filters are designed for:

Enhanced Signal Strength: Our filters provide high transmission rates to ensure clear and accurate data capture, even in challenging low-light conditions.

Angle-Insensitive Options: For applications like LIDAR, where performance at varying angles is crucial, Chroma can design filters with low angle sensitivity, ensuring optimal performance across a range of incident light angles.

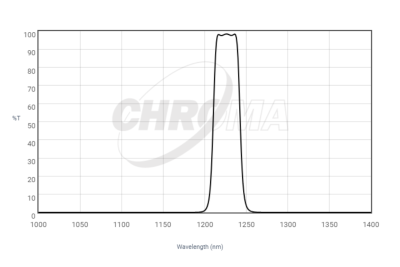

Superior Spectral Precision in SWIR Applications

SWIR applications require precise control over specific wavelengths to deliver optimal performance. Chroma’s SWIR filters offer:

Tight Wavelength Control: Our filters maintain strict tolerances, providing precise spectral control across narrow and wide bands, ensuring accurate isolation of critical SWIR wavelengths.

Steep Spectral Edges: The steep edges of our filters enable precise wavelength separation, minimizing cross-talk and maximizing clarity in hyperspectral and multispectral imaging systems.

Square Bandpass for High Contrast: Sputter-coated filters with square bandpass shapes deliver superior contrast and resolution, making them ideal for high-speed machine vision applications that need precise filtering.

Durability for Harsh Environments

Built to withstand harsh conditions, including significant temperature variations and high humidity, Chroma’s sputter-coated filters are ideal for use in the most demanding industrial environments.

Explore our case study for an example of how we optimized filters for SWIR-based pipeline sensors.

Commitment to Quality and Consistency

We understand that the reliability and consistency of our filters are critical to your processes. That's why we maintain rigorous quality control measures throughout our manufacturing processes. As an ISO-certified company, we adhere to strict standards in our operations.

In addition, our comprehensive quality assurance procedures ensure that every filter we produce consistently meets your exact requirements, providing you with the confidence and peace of mind needed for your critical inspection applications.

Catalog Filters for SWIR Applications

For the most common filters required, we offer a range of catalog options which are frequently used in Short-Wave Infrared applications including our:

These filter types represent just a fraction of our capabilities and our extensive experience allows us to address a wide array of optical filtering needs for high-performance SWIR applications.

Additionally, we have a vast array of existing designs and a comprehensive inventory spanning the spectral range from the ultraviolet (UV) to the mid-wave infrared (MWIR). Often this allows us to quickly customize filters to your specific requirements and ship fast, minimizing lead times.

Step-by-Step Custom Filter Design Process

For filter designs outside of our catalog offerings, we pride ourselves on our ability to meet even the most challenging filter requirements. Our design process ensures that you get the optimal filter for your application every time with our step-by-step process:

Consultation: First, our team will collaborate with you to thoroughly understand your specific needs and application challenges.

Design Optimization: With our extensive database of over 20,000 unique filter designs, we tailor solutions to meet or exceed your application requirements while optimizing for cost-effectiveness. Whether adapting an existing design or creating a new one, we ensure you achieve the best performance without paying for unnecessary features.

Simulation and Prototyping: We use proprietary optical modeling tools to simulate filter performance and, when necessary, create prototypes for testing.

Manufacturing: Once the design is finalized, we produce your filters using our state-of-the-art facilities, ensuring the highest quality and consistency.

Quality Assurance: Every filter undergoes rigorous testing to meet our exacting standards and your specific requirements.

With decades of experience manufacturing optical filters for demanding applications, we understand the unique challenges you face. Whether you need a minor modification to an existing design or a completely novel filter, Chroma's expertise ensures you receive the best performance and value possible, tailored precisely to your application.

Ready to Enhance Your SWIR Application?

Contact our team to discuss your specific requirements or request a quote.