Metrology

Chroma Technology’s commitment to precision and innovation extends to its Metrology capabilities. Using state-of-the-art measurement equipment, we ensure that our products meet the highest standards in optical performance. Our metrology team plays a crucial role in maintaining the quality of our optical filters, enabling high signal-to-noise, superior image quality, and the precision required in a variety of applications from life sciences and biomedical diagnostic instruments, to astronomical and scientific imaging.

Key Components of Chroma's Metrology

State-of-the-Art Testing Solutions

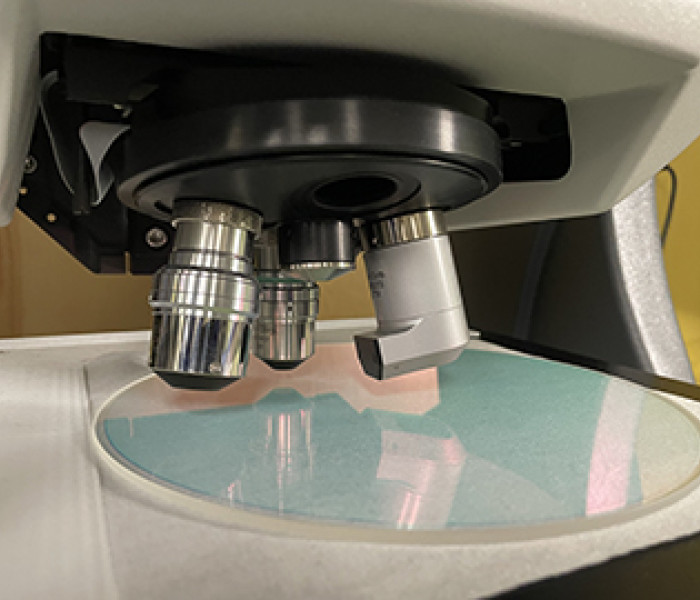

We have an assortment of advanced metrology equipment including:

Spectrophotometers for UV-SWIR

Fourier Transform Infrared (FTIR) Spectroscopy

Laser interferometers

Optical Profiler

Auto-collimators

Coordinate Measurement Machine (CMM)

We meticulously evaluate spectral characteristics, surface quality, and image quality. Chroma invests in technology that guarantees the unparalleled performance of our optical filters throughout the manufacturing process.

Customized Testing Protocols

Your unique applications deserve tailored solutions. Our metrology team collaborates closely with clients to craft customized testing protocols aligned with specific requirements. At Chroma, we pride ourselves on delivering optical filters that not only meet but exceed the performance expectations of demanding industries.

Quality Control

Measuring Spectral Performance

Chroma employs a suite of advanced Cary spectrophotometers, covering 200-NIR. We perform spectral measurements of every production lot to ensure filters meet specification requirements. We assign specifications for catalog products, which we've developed through 25 years of experience. For our OEM customers and those requesting bespoke parts, we provide the specified spectral performance.

Spectral Range | Dynamic Range | Spectral Resolution |

|---|---|---|

200-3300nm | 100%T → OD8 | Resolve spectral features 1 Å or greater |

Measuring Optical Properties

Using Zygo interferometers and custom-built autocollimators, Chroma can offer precise measurements of Transmitted Wavefront Distortion (TWD), surface flatness (Reflected Wavefront Distortion/2), and parallelism (wedge).

We measure physical dimensions of size according to specifications and perform routine surface quality inspections such as S/D (Scratch/Dig), and we ensure that shipped products are free of any cosmetic defects.

Transmitted | Surface | Parallelism |

|---|---|---|

1/20λ | 1/20λ | 1 arcsecond |

Pioneering Continuous Improvement

In the dynamic field of optics, staying ahead is imperative. Chroma Technology's metrology team works closely with our various engineering disciplines to advance our capabilities which can include exploring new measurement techniques. This commitment to continuous improvement ensures that our products remain at the forefront of performance and innovation.

Explore the world of optical excellence with Chroma

Chroma Technology's metrology capabilities are the keystone of our dedication to delivering exceptional optical solutions. Through state-of-the-art equipment, precision calibration, customized testing protocols, rigorous quality control, and an unwavering commitment to continuous improvement, we ensure that our optical filters meet the stringent requirements of diverse industries.