Pinholes in Optical Coatings: Causes, Effects, and Solutions

Optical coatings play an important role in a wide range of industries, from medical devices to satellite communication. These coatings help control light by reflecting or transmitting different wavelengths. However, even an extremely small imperfection—known as a pinhole—can drastically affect performance, leading to serious issues in critical applications.

Pinholes are tiny defects that can form in the coating process. While they may be small, their effects can be significant, leading to issues such as light leakage or reduced durability. That is why at Chroma, we take extensive measures to prevent pinholes, ensuring our optical filters meet the highest standards of quality.

Let’s look at what pinholes are, how they get created and finally, how Chroma prevents them.

What Are Pinholes?

Pinholes are tiny defects that most often look like small holes or craters in the surface of an optical coating. They can form for several reasons, including:

Contaminants: Dust, dirt, or other particles can land on the substrate during the coating process. These contaminants can cause the formation of tiny nodules during the coating process. When these nodules flake off, they leave behind pinholes.

Imperfections in the Substrate: Before a coating is applied, the base material, known as the substrate, needs to be extremely smooth and clean. If there are defects in the substrate, these can lead to pinholes in the coating.

Pinholes may seem minor, but they can cause problems in high-precision applications where even the smallest defect can affect performance.

Anatomy of a Pinhole

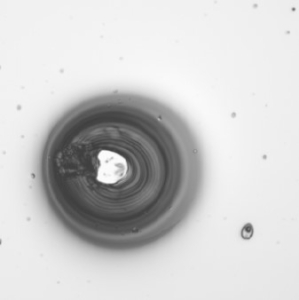

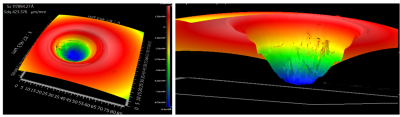

To truly grasp why pinholes are a significant challenge in optical coatings, it’s important to understand their structure. Pinholes are not just simple, uniform holes; they have a complex topography that can affect how they interact with light.

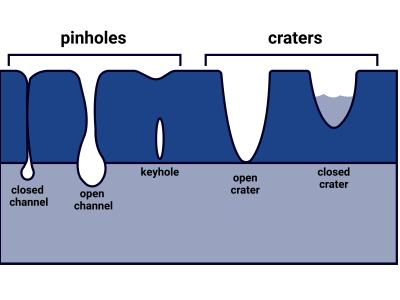

Pinholes can vary greatly in their shape and depth. Some pinholes are open, extending all the way through the coating and creating a direct pathway for light or other substances to pass through. These open pinholes are particularly problematic in optical filters that need to block or reflect specific wavelengths of light, as they can allow unwanted light to leak through.

Other pinholes are partially filled in, forming either a keyhole or close channel structure beneath the surface of the coating. While these closed pinholes don’t go all the way through, they can still result in decreased performance of the optical coating.

Then there are crater-like pinholes. These craters can occur in multiple ways such as when debris present on the surface of the substrate flakes away. Craters can be shallow or deep and may not always be visible to the naked eye, but they still compromise the integrity of the coating and its performance.

The Impact of Pinholes on Optical Performance

Even though pinholes are small, they can have a big impact on the performance of an optical filter including:

Light Leakage: Pinholes can let unwanted light pass through the filter, reducing the optical density of the filter.

Reduced Durability: Pinholes can weaken the coating, making it more likely to fail over time.

Imaging Artifacts: In imaging systems, pinholes can create artifacts that distort the final image.

For those who rely on precise and reliable optical filters, the presence of pinholes can lead to costly disruptions and unexpected downtime. That’s why at Chroma, we are dedicated to preventing pinholes at every stage of our process, ensuring that our products meet the highest standards of quality and performance.

Preventing Pinholes: Our Comprehensive Manufacturing Process

Preventing pinholes starts long before the coating process begins. At Chroma, we maintain over 17,000 square feet of clean room space designed to keep out dust, dirt, and other particles that can cause defects such as pinholes in an effort to minimize the risk of contamination during the coating process.

In addition, we regularly monitor and have our cleanrooms certified to ensure they meet the standards needed to manufacture our high-performance coatings. By keeping our cleanrooms as clean as possible, we significantly reduce the chances of pinholes forming during the coating process.

Our efforts to prevent pinholes extend beyond our cleanroom facilities. We have also developed a manufacturing process that focuses on eliminating potential sources of defects at every stage including:

Critical Cleaning Operations: Before we apply any coatings, we carefully clean each substrate to remove dust, stains, and debris. This helps create a clean surface that’s less likely to develop pinholes.

Proprietary Coating Technology: We use custom-designed equipment and processes tailored to our specific needs, allowing us to apply coatings with exceptional precision. This reduces the risk of pinholes and ensures high-quality results.

Inspection Protocols: Our inspection protocols involve multiple stages of quality checks to identify and address defects, ensuring that only the best filters reach our customers.

Continuous Monitoring: We continuously monitor our manufacturing environment to catch any potential issues early. This helps us maintain the highest level of quality and minimize yield loss due to defects.

We understand that even the smallest defects can have a big impact on the performance of optical filters. That’s why we invest in advanced cleanrooms and strict manufacturing processes to prevent pinholes and other defects. Our commitment to quality ensures that our customers receive the best possible products—free from imperfections that could compromise their work and deliver consistently superior performance.

Want to learn more about how we ensure the highest quality in our optical filters? Visit our Capabilities page or Contact Us to learn more.

Learn More About Optical Filters

Optical Filter Cleaning Guide

Discover the best practices for cleaning your optical filters, including the recommended materials and techniques.

Handbook of Optical Filters

Gain a solid foundation in the basics of using optical filters, especially in fluorescence microscopy.

Optical Filter Glossary

Your guide to the key terms and concepts essential for working with optical filters.